Diagnostic X-ray Machines

Examples: Radiography and fluoroscopy machines used in medical imaging.

Importance:Ensures accurate and high-quality diagnostic images with minimal radiation exposure to patients and healthcare professionals.

Computed Tomography (CT) Scanners

Examples: CT machines for detailed cross-sectional imaging.

Importance: Quality assurance is crucial to maintain image resolution, optimize dose levels, and ensure safe and precise diagnostic information.

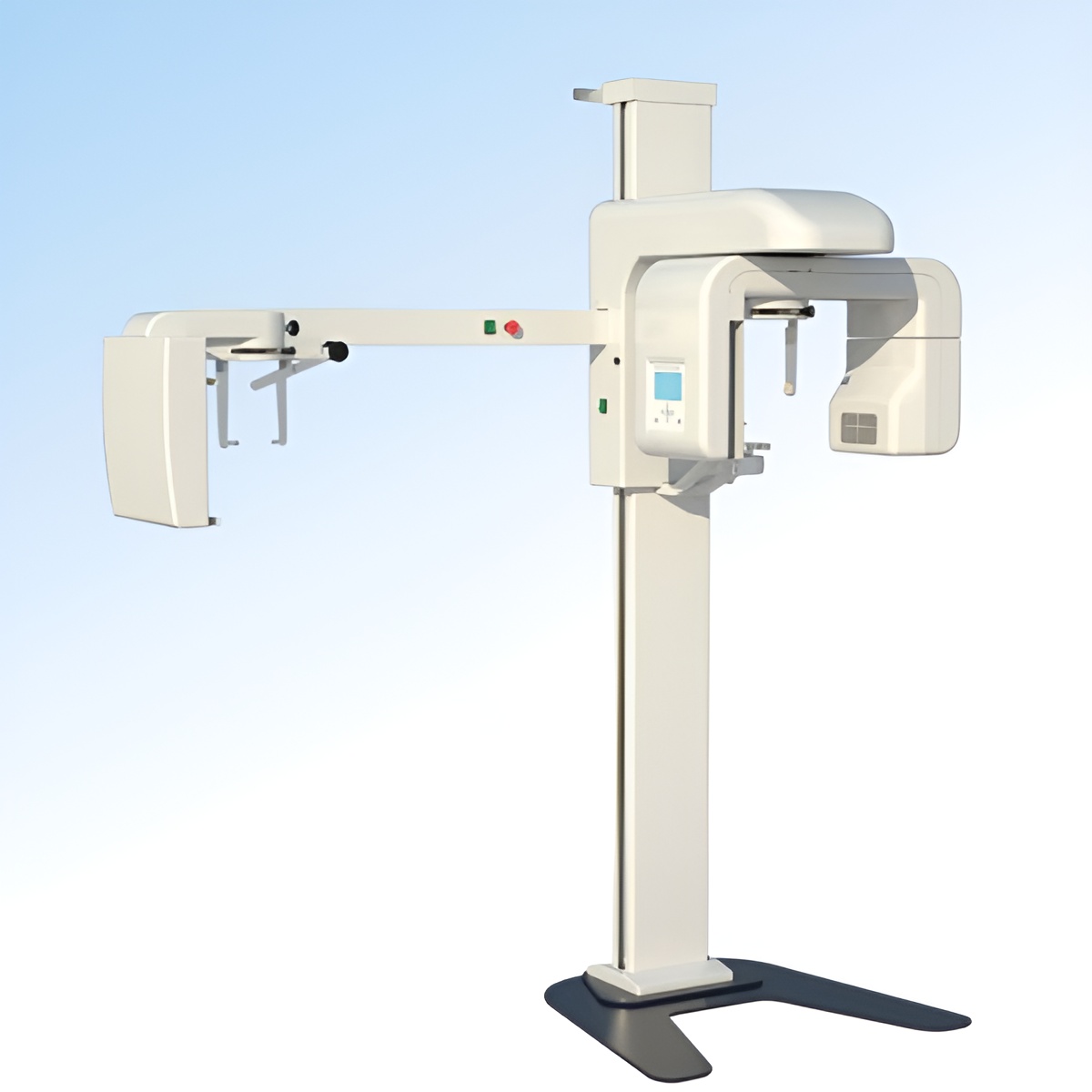

Dental X-ray Machines

Examples: Intraoral and extraoral dental X-ray units.

Importance: Quality control is essential for dental imaging to provide clear and detailed images for diagnosis while minimizing radiation exposure to patients.

Fluoroscopy Systems

Examples: C-arm fluoroscopy units used in surgical and interventional procedures.

Importance: Quality control ensures real-time imaging during procedures with optimal image quality and radiation safety for both patients and medical staff.

Portable X-ray Machines

Examples: Mobile X-ray units for bedside imaging.

Importance: Quality assurance is necessary for portable X-ray machines to maintain imaging accuracy and safety in diverse clinical settings.

Dual-Energy X-ray Absorptiometry (DEXA) machine

Examples: Dual-Energy X-ray Absorptiometry (DEXA) machines used for measuring bone mineral density in patients.

Importance: Ensures accurate bone mineral density measurements for osteoporosis diagnosis and fracture risk assessment. Quality control measures, including calibration, phantom scans, image quality control, and technologist training, are crucial for precise results, patient safety, and compliance with industry standards.